Excellent control performance and high precision

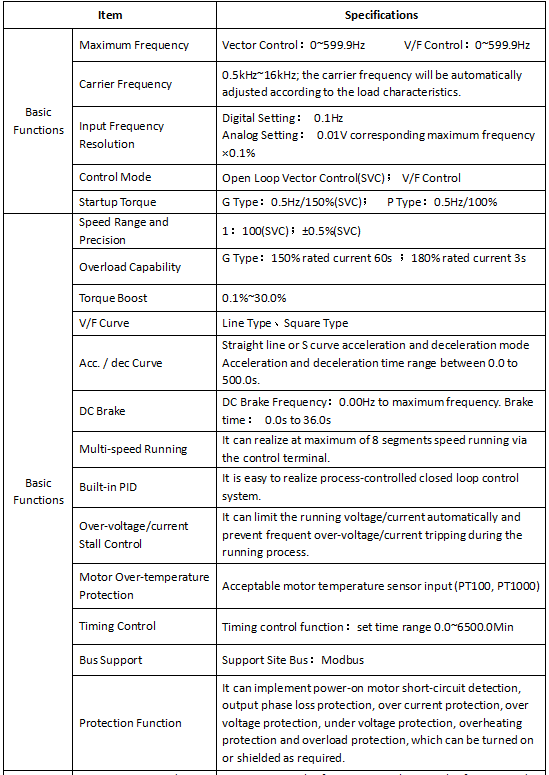

✔ Advanced dual control mode: Supports both open-loop vector control (SVC) and V/F control, and can be flexibly selected according to different application scenarios (such as high torque loads or fans and pumps), balancing high performance and versatility.

✔ Powerful start-up and low-speed performance: Under open-loop vector control, 150% of the start-up torque can be provided at 0.5Hz (universal models), ensuring smooth start-up of the equipment and overcoming large inertial loads.

Rich features and high reliability

✔ Equipped with IP54 protection level: The frequency converter has strong dust and splash proof capabilities

✔ Comprehensive protection function: Provides comprehensive protection functions including motor short circuit, phase loss, overcurrent, overvoltage, undervoltage, overheating, overload, etc., and can be turned on or off as needed to ensure equipment and personnel safety and reduce unexpected shutdowns.

✔ Built in PID controller: With integrated PI control function, it is easy to build a process closed-loop control system (such as constant pressure water supply and constant tension control) without the need for an external controller, simplifying the system structure and reducing costs.

Powerful universality and ease of use

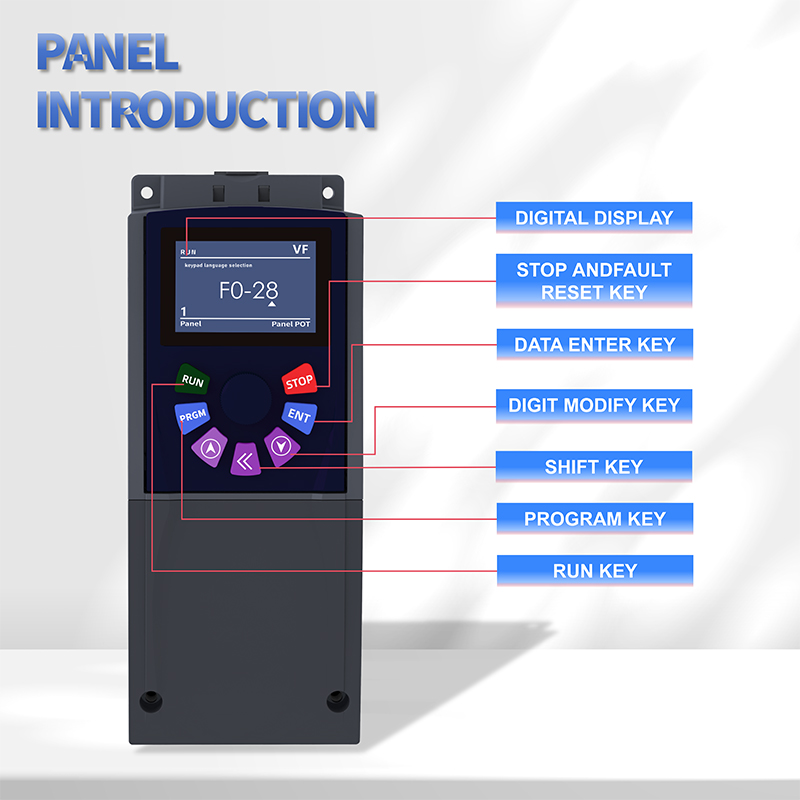

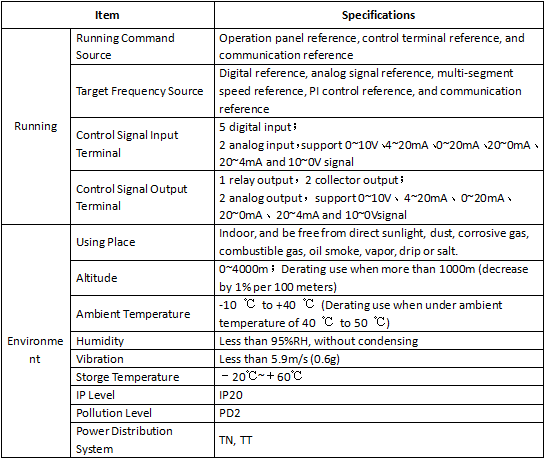

✔ Multiple control methods: Supports setting operation commands and frequencies through the operation panel, control terminals, and communication. Provides multiple frequency setting methods such as digital settings, analog signals, multi speed (up to 8 speed), PI, and communication to meet different on-site needs.

✔ Multi functional application support: Supports multi-stage operation, DC braking, timed control (up to 6500 minutes), and motor thermal protection (directly connected to PT100/PT1000 sensors), suitable for various application scenarios such as machine tools, conveyor belts, elevators, fans, and water pumps.

Convenient integration and communication capabilities

✔ Standard communication interface: Built in Modbus communication protocol, can easily connect to upper computer systems (such as PLC, DCS, industrial control computer) or configuration software, achieve remote monitoring and cluster control, and provide a foundation for building intelligent factories.

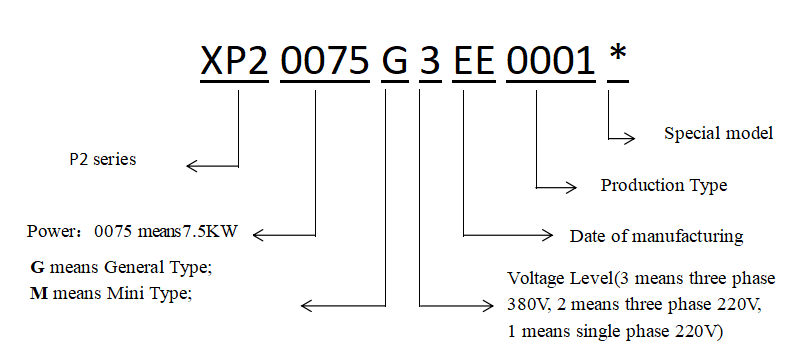

Products Nameplate:

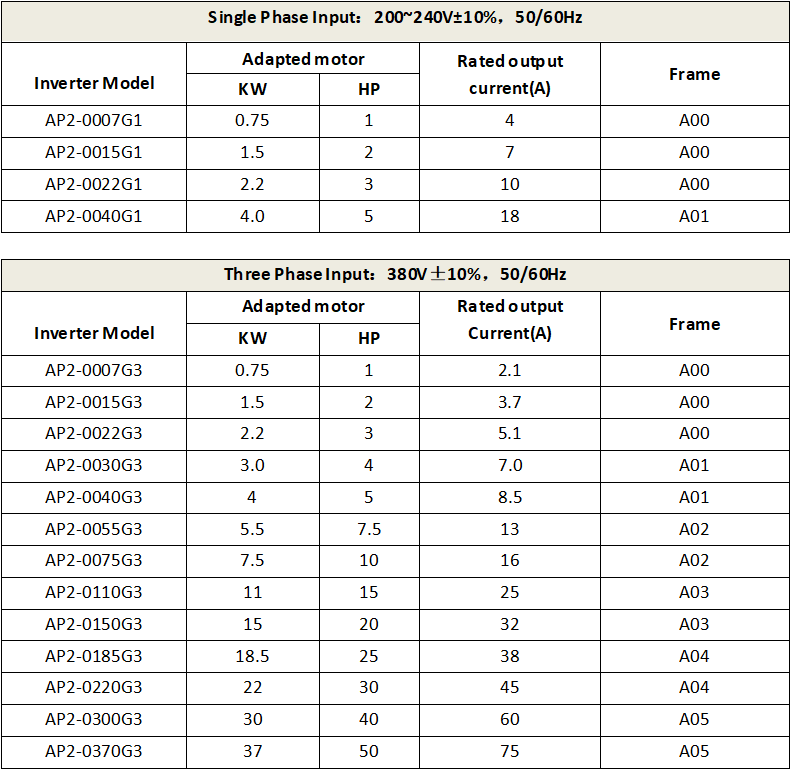

AP2 General type Inverter Model:

Technical Specifications:

| File Name | Format | Time | Download |

|---|---|---|---|

| AP2 series Inverter User Guide |

|

Aug 25, 2025 |