Characteristics of 900 Series Permanent Magnet Synchronous Inverter:

1. Refined design, strong temperature resistance, high power density, higher energy conversion efficiency, and more stable operation.

2. Efficient and precise control performance

Support vector control and V/F control, up to 0-500Hz, suitable for high-speed motor requirements. Carrier frequency: 0.5kHz~16kHz, can be automatically adjusted to optimize load matching, reduce noise and loss.

3. Flexible application adaptability

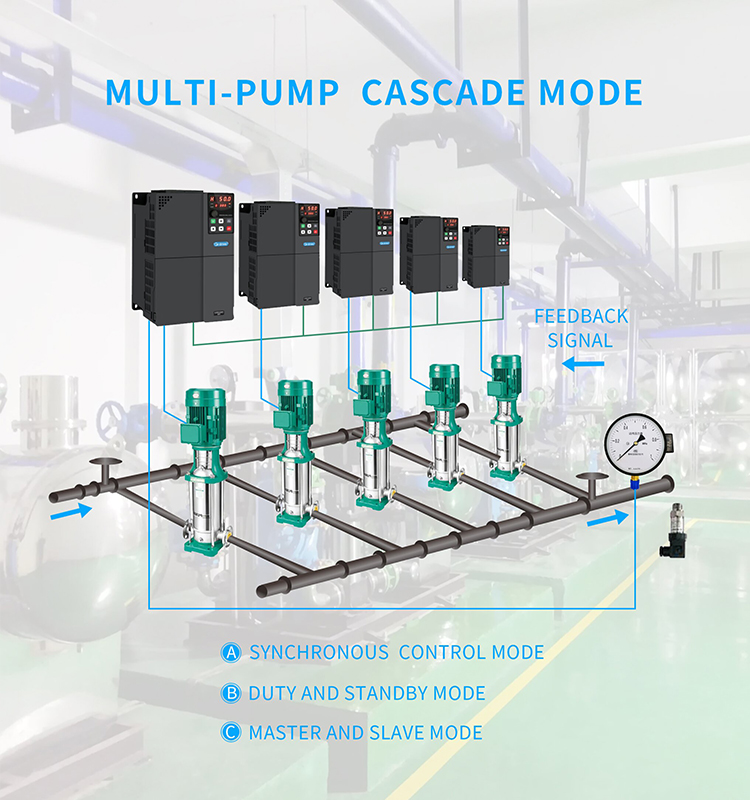

Multi speed operation: By controlling the terminals, up to 4 speeds can be achieved to meet complex process requirements. Built in PI control: realizes closed-loop control, accurately adjusts parameters such as flow and pressure.

4. Strong environmental adaptability

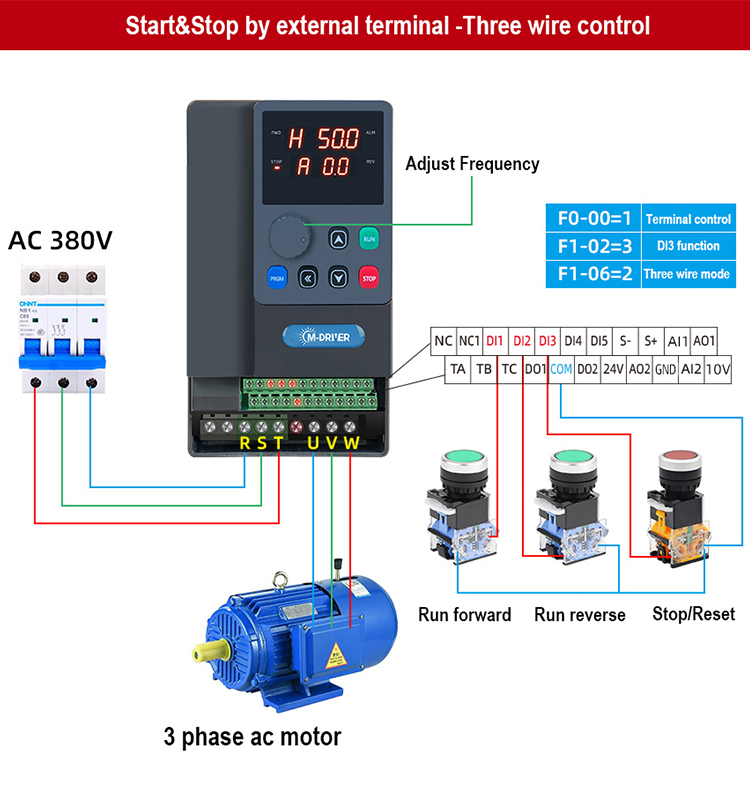

Protection level: IP20, Suitable for indoor environments without dust or corrosive gases. Communication support: Built in Modbus protocol, easy access to automation control systems, enabling remote monitoring.

5. Convenient operation and maintenance

Supports multiple input methods such as panels, terminals, analog signals, and communication, making operation more flexible. It can be remotely started and stopped through the operation panel, control terminals, or communication. Adaptive noise reduction: Automatic adjustment of carrier frequency, optimization of electromagnetic compatibility (EMC), and reduction of interference.

Application of 900 Series Permanent Magnet Synchronous Inverter:

Permanent magnet synchronous motor frequency converter is a general-purpose high-performance vector frequency converter, mainly used to control and regulate the speed and torque of three-phase AC synchronous motors. This permanent magnet frequency converter has the core advantages of high-precision control, strong overload capacity, and wide environmental adaptability. It is suitable for multiple scenarios such as industrial automation, fans and pumps, and heavy-duty machinery, balancing efficiency and reliability. It is an ideal driving solution for complex working conditions.

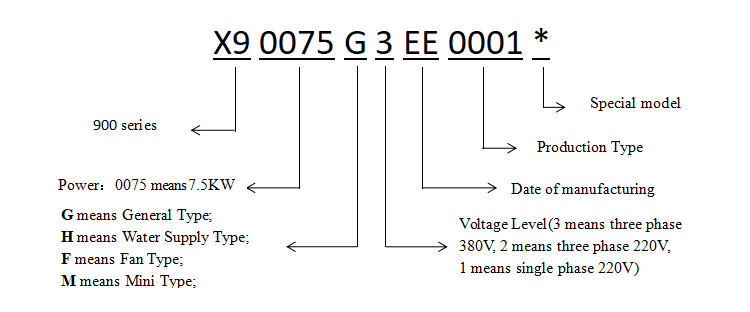

Products Nameplate:

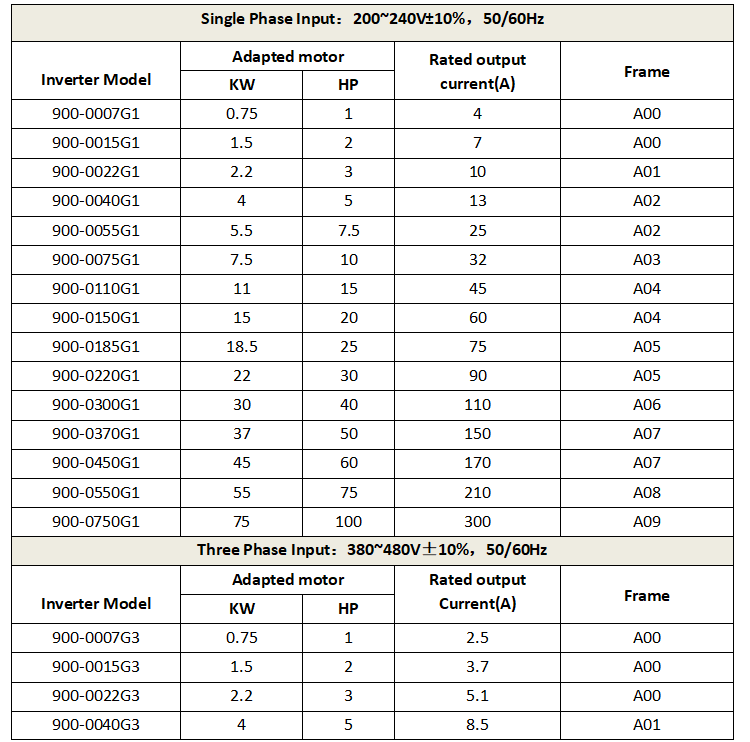

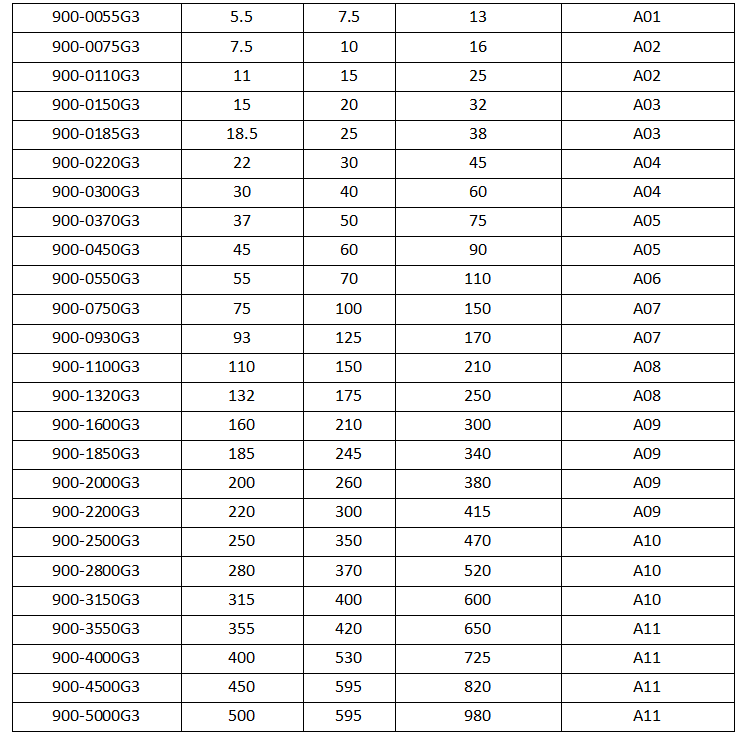

900 General type Inverter Model:

Technical Specifications:

Item | Specifications | |

Basic Functions | Maximum Frequency | Vector Control:0~599.9Hz V/F Control:0~599.9Hz |

Carrier Frequency | 0.5kHz~16kHz; the carrier frequency will be automatically adjusted according to the load characteristics. | |

Input Frequency Resolution | Digital Setting: 0.1Hz Analog Setting: 0.01V corresponding maximum frequency ×0.1% | |

Control Mode | Open Loop Vector Control(SVC); V/F Control | |

Startup Torque | G Type:0.5Hz/150%(SVC); P Type:0.5Hz/100% | |

Basic Functions | Speed Range and Precision | 1:100(SVC);±0.5%(SVC) |

Overload Capability | G Type:150% rated current 60s ;180% rated current 3s

| |

Torque Boost | 0.1%~30.0% | |

V/F Curve | Line Type、Square Type | |

Acc. / dec Curve | Straight line or S curve acceleration and deceleration mode Acceleration and deceleration time range between 0.0 to 500.0s. | |

DC Brake | DC Brake Frequency:0.00Hz to maximum frequency. Brake time: 0.0s to 36.0s | |

Multi-speed Running | It can realize at maximum of 8 segments speed running via the control terminal. | |

Built-in PID | It is easy to realize process-controlled closed loop control system. | |

Over-voltage/current Stall Control | It can limit the running voltage/current automatically and prevent frequent over-voltage/current tripping during the running process. | |

Motor Over-temperature Protection | Acceptable motor temperature sensor input (PT100, PT1000) | |

Timing Control | Timing control function:set time range 0.0~6500.0Min | |

Bus Support | Support Site Bus:Modbus | |

Protection Function | It can implement power-on motor short-circuit detection, output phase loss protection, over current protection, over voltage protection, under voltage protection, overheating protection and overload protection, which can be turned on or shielded as required. | |

Running | Running Command Source | Operation panel reference, control terminal reference, and communication reference |

Target Frequency Source | Digital reference, analog signal reference, multi-segment speed reference, PI control reference, and communication reference | |

Control Signal Input Terminal | 5 digital input; 2 analog input,support 0~10V、4~20mA、0~20mA、20~0mA、20~4mA and 10~0V signal | |

Control Signal Output Terminal | 1 relay output,2 collector output; 2 analog output,support 0~10V、4~20mA、0~20mA、20~0mA、20~4mA and 10~0Vsignal | |

Environment | Using Place | Indoor, and be free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapor, drip or salt. |

Altitude | 0~4000m;Derating use when more than 1000m (decrease by 1% per 100 meters) | |

Ambient Temperature | -10 ℃ to +40 ℃ (Derating use when under ambient temperature of 40 ℃ to 50 ℃) | |

Humidity | Less than 95%RH, without condensing | |

Vibration | Less than 5.9m/s (0.6g) | |

Storge Temperature | -20℃~+60℃ | |

IP Level | IP20 | |

Pollution Level | PD2 | |

Power Distribution System | TN, TT | |

| File Name | Format | Time | Download |

|---|---|---|---|

| 900 Series VFD Manual |

|

Dec 26, 2024 |