Characteristics of 900 Series Fan and Pump Drive:

1. Support terminal and panel control (Run/Stop),Support speed regulation via buttons and analog inputs

2. Analog inputs compatible with voltage (0-10V) and current (4-20mA) signals,Multi-speed control capability (up to 4 preset speeds)

3. Built-in constant pressure control for water supply systems,High protection level with time-saving parameter configuration

4. Detachable keypad design for flexible operation,Robust construction for harsh environment applications

5. Dual control mode (terminal/panel operation),Flexible speed command options (analog/digital)。Multi-function analog inputs/outputs,Specialized pump control functions

6. User-friendly interface design,Wide environmental adaptability

Application of 900 Series Fan and Pump Drive:

Material handling (lifting, conveying equipment)

Processing and manufacturing (machine tools, metal processing)

Process industries (petrochemical, metallurgical, cement)

Municipal engineering (water supply, sewage treatment)

New energy (wind power, photovoltaic supporting)

Packaging Textile (Printing, Chemical Fiber, Packaging Machinery)

Transportation (electric vehicles, rail transit) and other fields.

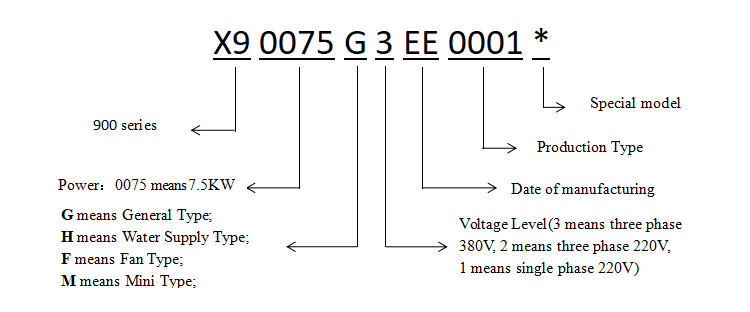

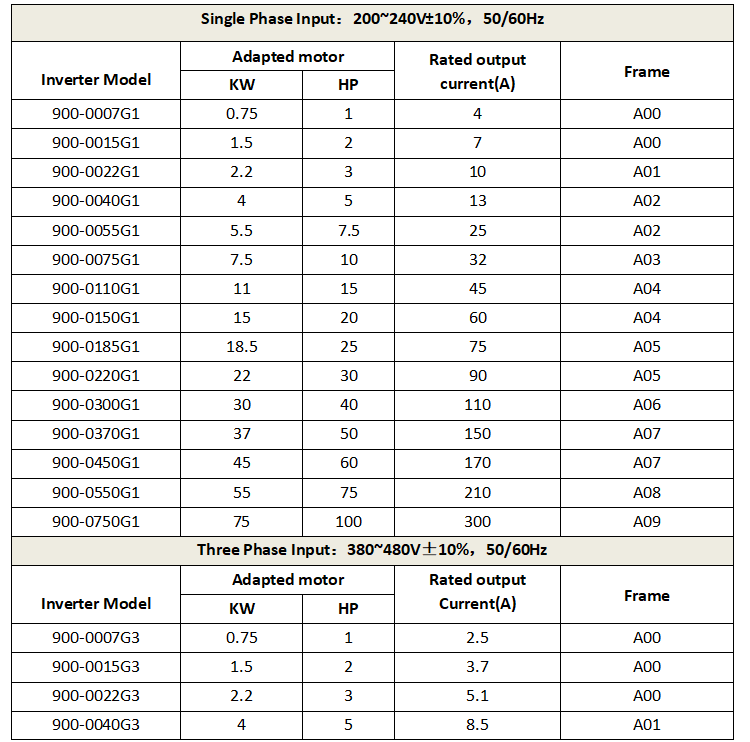

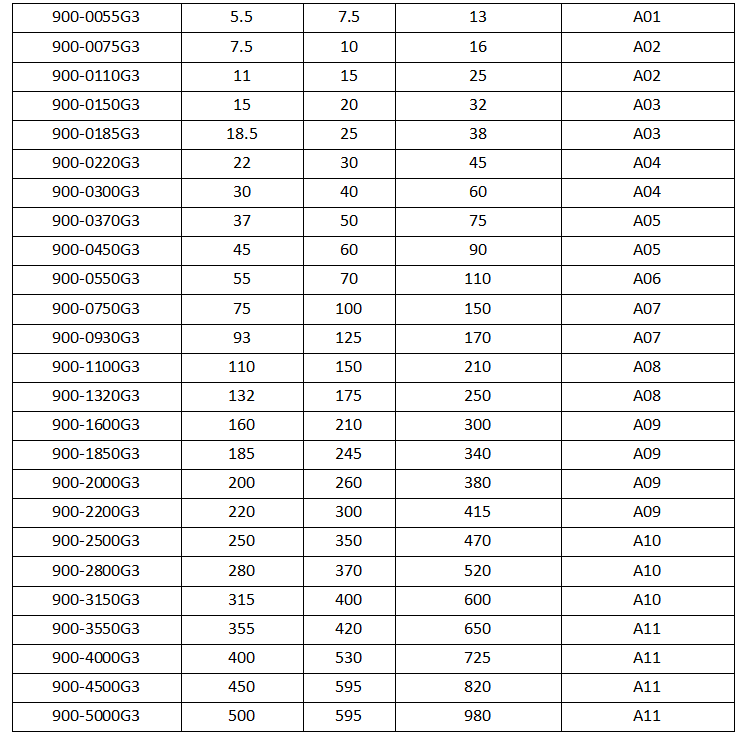

Products Nameplate:

900 General type Inverter Model:

Technical Specifications:

Item | Specifications | |

Basic Functions | Maximum Frequency | Vector Control:0~500Hz V/F Control:0~500Hz |

Carrier Frequency | 0.5kHz~16kHz; the carrier frequency will be automatically adjusted according to the load characteristics. | |

Input Frequency Resolution | Digital Setting: 0.1Hz Analog Setting: 0.01V corresponding maximum frequency ×0.1% | |

Control Mode | Open Loop Vector Control(SVC); V/F Control | |

Startup Torque | G Type:0.5Hz/150%(SVC); P Type:0.5Hz/100% | |

Basic Functions | Speed Range and Precision | 1:100(SVC);±0.5%(SVC) |

Over Load Capability | G Type:150% rated current 60s ;180% rated current 3s P Type:120% rated current 60s ;150% rated current 3s | |

Torque Boost | 0.1%~30.0% | |

V/F Curve | Line Type、Square Type | |

Acc. / dec Curve | Straight line or S curve acceleration and deceleration mode Acceleration and deceleration time range between 0.0 to 500.0s. | |

DC Brake | DC Brake Frequency:0.00Hz to maximum frequency. Brake time: 0.0s to 36.0s | |

Multi-speed Running | It can realize at maximum of 4 segments speed running via the control terminal. | |

Built-in PID | It is easy to realize process-controlled closed loop control system. | |

Over-voltage/current Stall Control | It can limit the running voltage/current automatically and prevent frequent over-voltage/current tripping during the running process. | |

Motor Over-temperature Protection | Acceptable motor temperature sensor input (PT100, PT1000) | |

Timing Control | Timing control function:set time range 0.0~6500.0Min | |

Bus Support | Support Site Bus:Modbus | |

Protection Function | It can implement power-on motor short-circuit detection, output phase loss protection, over current protection, over voltage protection, under voltage protection, overheating protection and overload protection, which can be turned on or shielded as required. | |

Running | Running Command Source | Operation panel reference, control terminal reference, and communication reference |

Target Frequency Source | Digital reference, analog signal reference , multi-segment speed reference, PI control reference, and communication reference | |

Control Signal Input Terminal | 4 digital input; 2 analog input,support 0~10V、4~20mA and 0~20mA signal | |

Control Signal Output Terminal | 2 relay output; 1 analog output,support 0~10V、4~20mA and 0~20mA signal | |

Environment | Using Place | Indoor, and be free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapor, drip or salt. |

Altitude | 0~4000m;Derating use when more than 1000m (decrease by 1% per 100 meters) | |

Ambient Temperature | -10 ℃ to +40 ℃ (Derating use when under ambient temperature of 40 ℃ to 50 ℃) | |

Humidity | Less than 95%RH, without condensing | |

Vibration | Less than 5.9m/s (0.6g) | |

Storge Temperature | -20℃~+60℃ | |

IP Level | IP20 | |

Pollution Level | PD2 | |

Power Distribution System | TN , TT | |

| File Name | Format | Time | Download |

|---|---|---|---|

| 900 Series VFD Manual |

|

Feb 27, 2025 |